ADVANTAGES OF CNC MACHINING

To understand why CNC machining is so crucial for success in the automotive industry, it’s important to consider the advantages of the technology. A typical automotive manufacturing line is characterised by extremely high production rates, consistency and cost reduction.

CNC machines can be set up to churn out a specific part 24 hours a day without rest or complaint. This creates massive labour savings, since an operator does not need to attend to the machine constantly and can often run multiple machines at once.

In the automotive industry, CNC Machining has been enthusiastically adopted, as manufacturers across the globe seek to benefit from the process’ many perks, including speed, automation, repeatability and more.

Production Speed:

For medium to high production volumes, CNC Machining offers rapid production times compared to traditional machining. This is largely because of its automated nature, which eliminates the need to lengthy and labour-intensive manual machining. There are also steps that can be taken in the production planning process to speed up and optimize the machine’s run time, including material choice and part tolerances.

Automation:

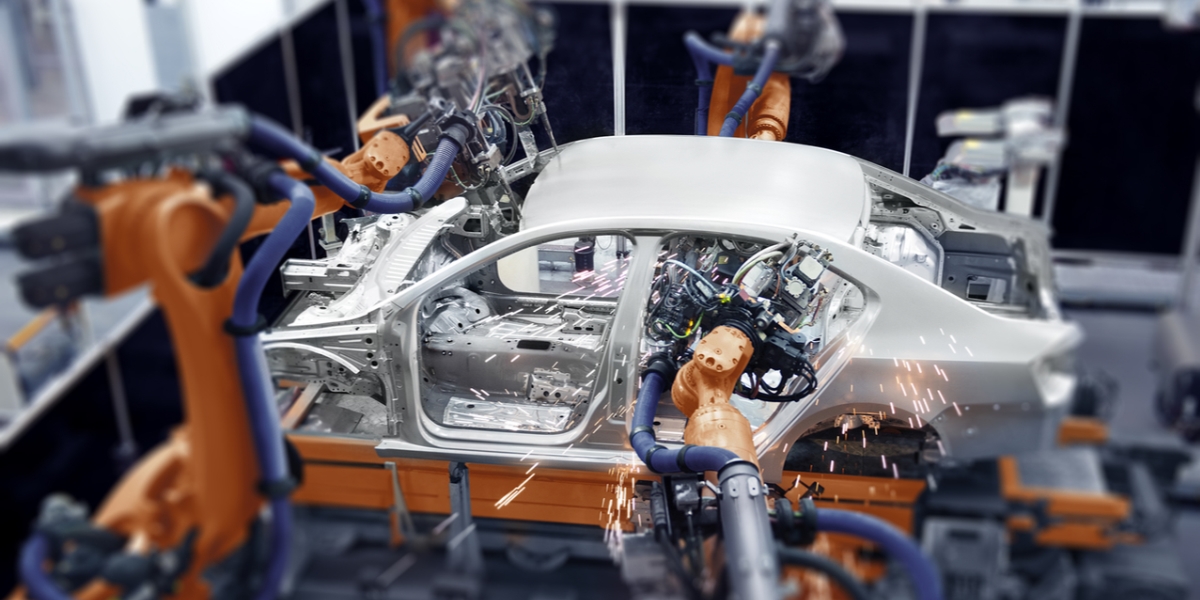

Automation is in itself an advantage of CNC Machining. Not only does it allow faster production times compared to manual processes, but it also makes the automotive manufacturing process more streamlined. If a part is sent to be manufactured on a CNC Machine and robotic arms can assist in the removal of the part once it is done, workers can dedicate more time to design and innovation tasks.

Respectability:

As a computer-controlled process, CNC Machining also brings with it a guarantee of respectability

a crucial element in any industrial-grade production setting. In the automotive industry, ensuring that parts are consistent from batch to batch, so that each car rolled out is up to the same standard, is vital.

Precision:

In line with repeatability, CNC Machining is capable of achieving tight tolerances for parts that demand it—though costs can be reduced if tolerances are more lenient. For automotive applications especially, CNC Machining can meet the required tolerances for engine and other functional components. The process is also capable of producing complex parts for vehicles.

Customization:

Though it is perhaps not as well suited to customization as additive manufacturing, CNC Machining can be used in the automotive sector to produce customized parts with short lead times—either as one-offs or in small production volumes.

ACEM MANUFACTURING

CNC PARTS IN THE AUTOMOTIVE INDUSTRY IN MEXICO

The automotive industry in Mexico is growing at a tremendous pace due to significant demand. The Automotive Industry in Mexico is listed in the top ten largest exporters of the world.

Vehicles are made up of a wide range of components that are created by using almost every manufacturing process from casting and injection moulding, to vacuum forming. Some of the key automotive components that are typically made on CNC machines are:

• Shafts

• Valve Retainers

• Engine Blocks

• Pistons

• Timing Covers

• Bushings

• Secondary Machining Operations on Castings

• Transmission Cases

• Gears

• Brake Systems.

This list is by no means exhaustive, but simply provides an overview of the array of different types of parts that CNC machines can be used for within the transport industry.

It should be noted that CNC machining is also used to manufacture tooling for other manufacturing technologies. This can include highly complex moulding for injection moulding systems, through to creating dies for vacuum forming machines.

Transportation

Depending on where you are situated, sending material to a supplier can be incredibly expensive and time consuming. The pieces may be are extremely expensive due to their large volumen . Shipping costs are determined by looking at the volume and weight of a parcel, and volumen becomes a significant contributor when sending material via air freight. A nearby supplier lowers these costs; improving production costs.

It can unnecessarily increase the price of your part. Furthermore, if there is a failure on your part during machining then you will need to send another piece of material and this can significantly complicate matters by not only wasting money, but also wasting time.

A national supplier reduces the times and risks generated by having a supplier in another country or region of the world.

ACEM MANUFACTURING

PROTOTYPING APPLICATIONS OF CNC

CNC Machining can be used in the automotive industry for both prototyping and production applications. In the latter category, the process offers the benefit of producing high quality, functional prototypes, which can be tested and validated before going into production.

Because of the wide variety of materials compatible with CNC Machining, the process can be used to produce all manner of prototypes for vehicles, including metal or plastic parts for under the hood applications or to showcase design features for car interiors. Lighting components such as headlight covers, for instance, can be rapidly prototyped using CNC Machining and clear acrylic materials.

In the development of new car models, CNC Machining can also be used to rapidly produce high quality functional prototypes for testing performance.

CNC Machining can also be employed by OEMs for the production of customized components or rare replacement parts. In the restoration of vintage cars, computer-controlled processes such as CNC Machining and 3D printing can be used in combination with reverse engineering practices to create one-off parts which might otherwise be obsolete.

ACEM MANUFACTURING